'67-91 GM Dana 44 and 10 Bolt Crossover Steering System

Crossover Steering Cliff Notes (More info can be found under description)

- Crossover steering improves geometry and poor steering characteristics over stock push pull

- This kit requires a 2wd steering gear box which we have HERE

- This kit requires either Machining of your flat top knuckle HERE or an aftermarket knuckle HERE

- Installing this system requires a 2wd steering gear box

- For thicker spring packs (greater than 2.5") the spacer is needed.

Why do you need crossover steering?

Better on road handling

Because of the short draglink used in stock push/pull steering it is greatly affected by changes in driving surfaces. This creates an unstable feeling in the steering. With the longer draglink that is used in crossover steering you will have a more precise feel.

Full lock to lock steering off road

With stock push/pull steering you are unable to turn the wheel all the way when the suspension is flexed. Crossover steering corrects this problem

Less wear on spring bushings

With stock push/pull steering all the pressure is placed on the driver’s side spring making wear components fatigue faster. By switching to crossover steering the load gets spread between both springs increasing longevity of components.

Best way to correct steering after lift

Instead of using drop parts or blocks, crossover is a more precise and correct way to adjust your steering for lift height.

What is needed for crossover steering?

2wd steering gear box

A 2wd steering gear box is needed for crossover steering. The 2wd box has a fully splined sector shaft to accept the crossover steering pitman arm. A 4wd steering gear box uses a bolt pin sector shaft and will not work for crossover steering. There is not a pitman arm that will work with the 4wd steering gear box. We do carry brand new HD steering boxes that are preported for hydro assist. These are made from a new casting with all brand new internals. They can be found Here: 2wd Steering Gears

At least 2 inches of lift

2 inches of lift is the lowest height we can do crossover steering. From 2-3” of lift you may need to trim your stock crossmember or switch to one of our high clearance crossmembers. We carry the crossmembers here: High Clearance Engine Crossmember

Steering Gear Box Information

The year breaks for steering boxes are:

‘67-‘76 (flare fitting, 36 spline input)

‘77-‘79 (flare fitting, 30 spline input)

‘80-‘91 (o-ring, 30 spline input, applies to old body style straight axle trucks)

As long as you get a 2wd box from a truck in your vehicle’s year group, it should be a 100% bolt on installation

What about my sway bar?

The factory sway bar CANNOT be used with crossover steering. We do carry an aftermarket sway bar that does work with crossover Crossover Sway Bar

Information for 2-3” lifted trucks

Some trimming of the crossmember may be needed. The high clearance pitman arm is designed to hug the frame as close as possible. Sometimes the end needs to be trimmed down to clear the frame. This can be done with a cuttoff wheel. If you have the steering box frame plate it may require more trimming. Below is a picture of the trimmed end to clear the frame

Why use our crossover steering kit?

No cutting, welding, or fab work required!

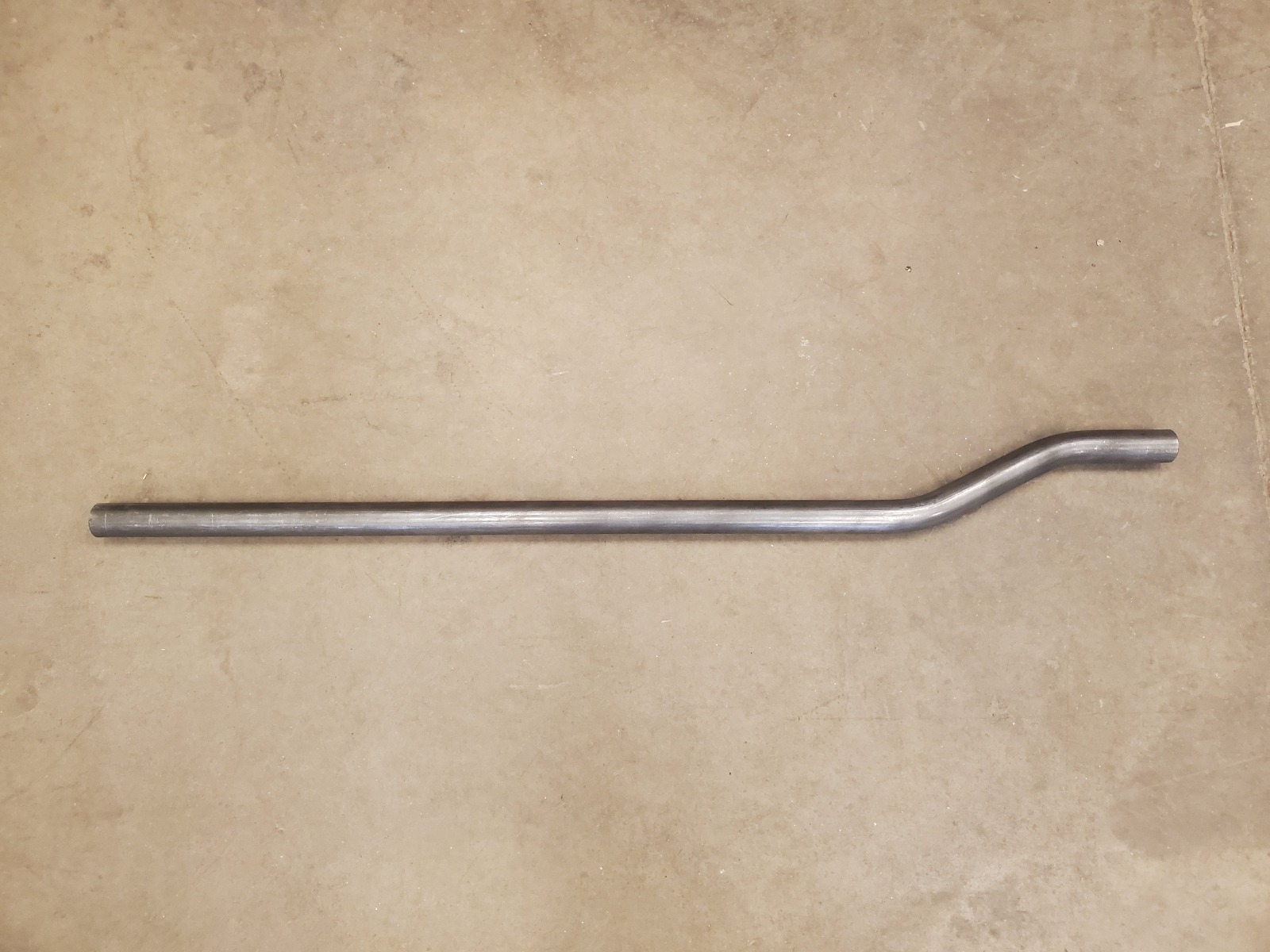

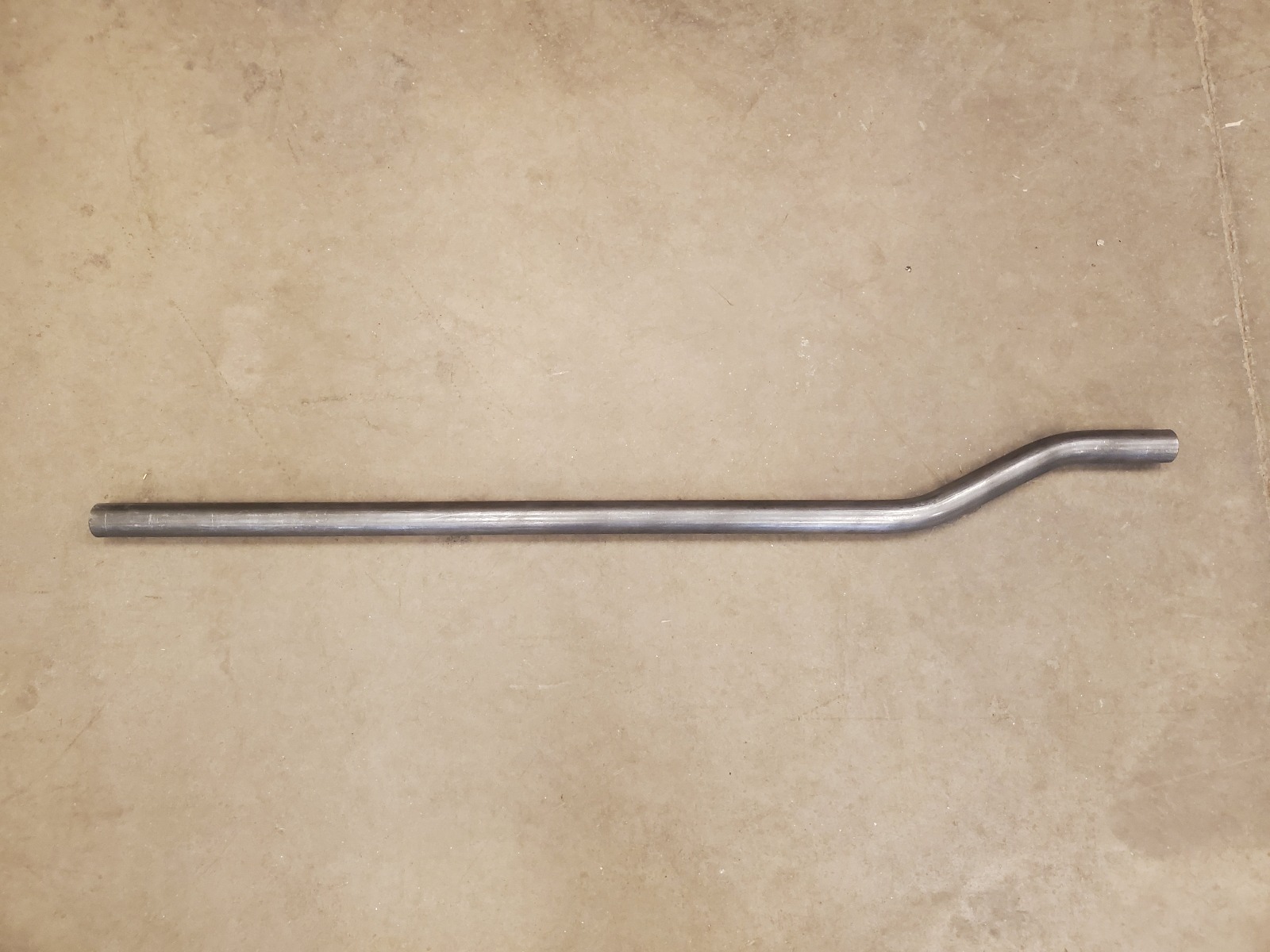

These crossover steering systems are designed specifically for the '67-91 Trucks and SUVs. Our draglinks are already cut to the correct length and directly threaded (not welded). If needed the draglink is bent to help tie rod end angle and to clear the engine/crossmember. Our draglinks use heavy wall 1020 DOM tubing and the best possible construction techniques.

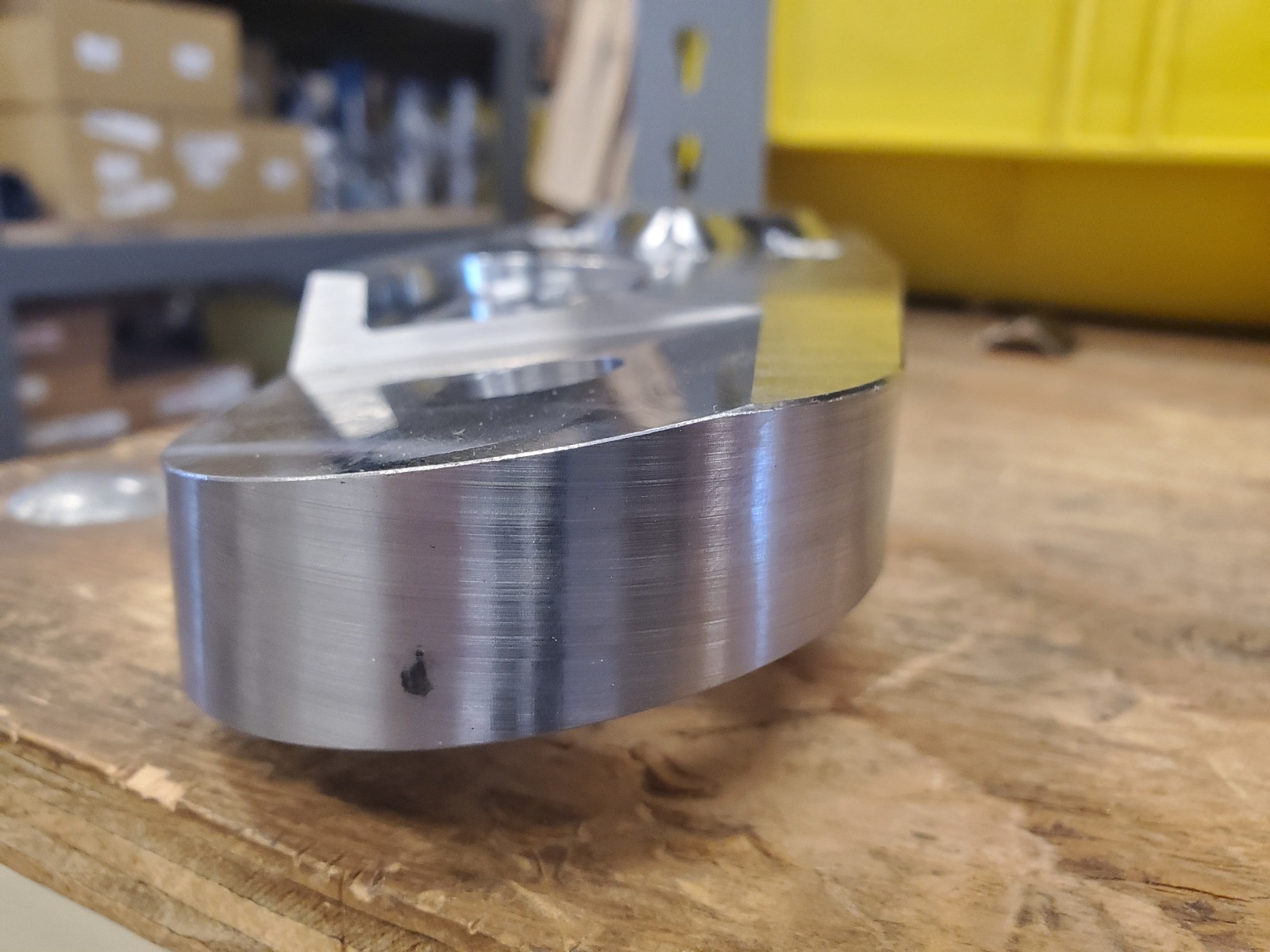

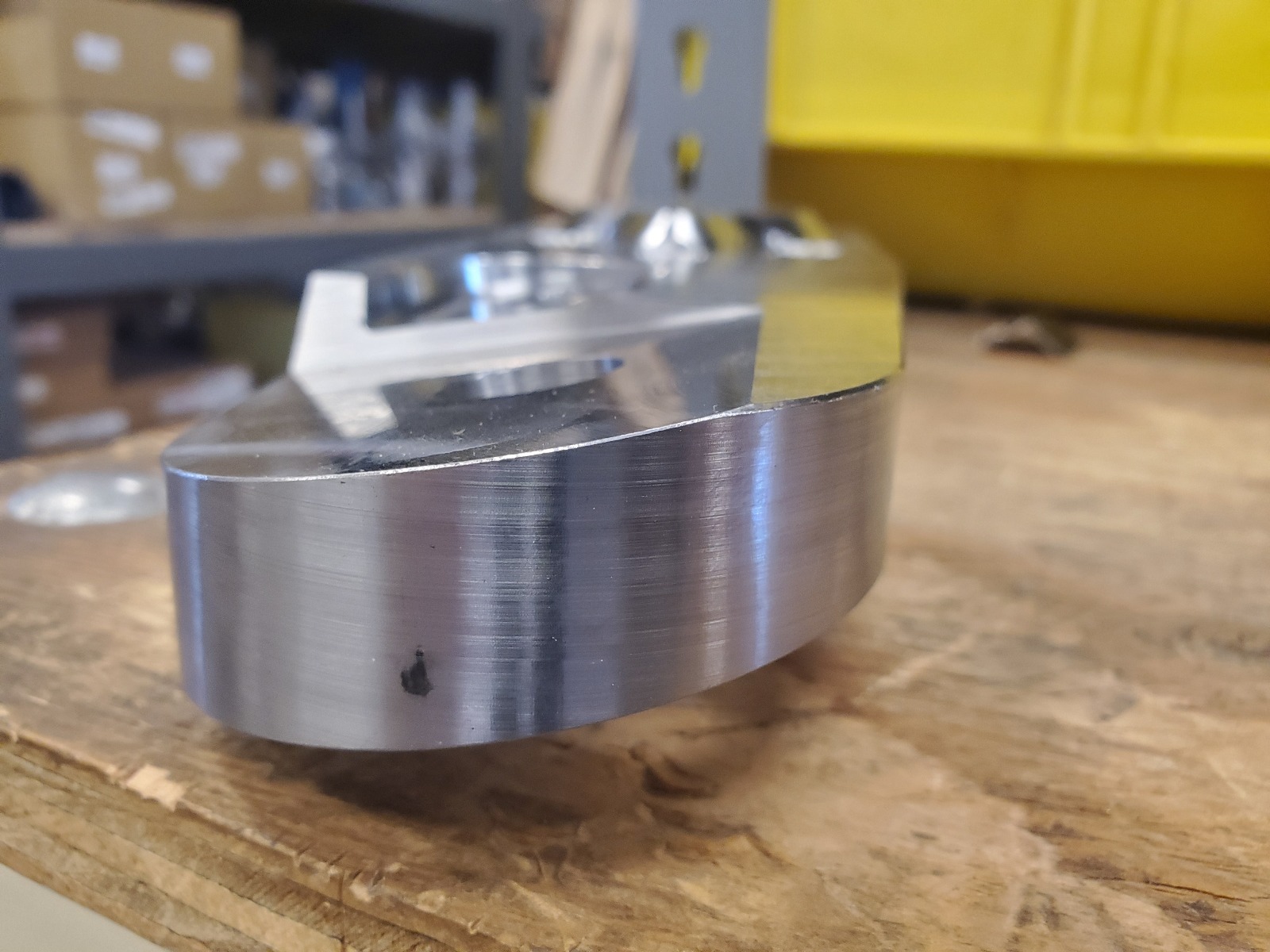

We use heavy duty metal on metal ends

Our tie rod ends are a metal-on-metal design with a preload spring on the bearing race (sort of like the upper kingpin on a Dana 60), that helps keep the joint tight even as the parts wear. Many joints are built with a plastic race that don't hold up well, see the picture below. Additionally, the plastic ends don't appear to have a heat treat, our band saw flew right through them. Notice the appearance of the metal-on-metal end (at right), it was very difficult to cut due to the heat treat.

We use the shortest tie rod ends possible (not OE draglink ends) because that can be crucial for engine crossmember clearance, often the offset bend needs to start as soon as possible. Our tie rod ends are a metal-on-metal design for the ultimate in durability, see details on that here.

Our tie rod ends are manufactured specifically for us. Factory GM draglink ends have good angle capacity, but have long shanks that can cause clearance issues. Factory GM tie rod ends are nice and short, but have very little angle capacity. Our ends are built with the best of both worlds, this is crucial in some applications (particularly 67-87 GM straight axle trucks) as many times the bend in the draglink has to start as soon as possible to clear the engine crossmember, the extra shank on draglink ends makes that impossible.

Billet steering arms

ARP Studs

We us ARP Studs with our kits to give you the ultimate in durability and strength

Our D60 arms retain the stock spring. Great for the daily driver who doesn't want to be adjusting pre-load all the time. We also carry spring eliminator kits here: Kingpin spring eliminator kit

For thicker spring packs (greater than 2.5") the spacer is needed.

Kit Contains

Pitman Arm: (This is the arm attached to the steering box shaft)

Steering Arm: This is the arm that attaches to the steering knuckle on the axle. It uses factory type studs, cone washers and locknuts to bolt to the knuckle. Our steering arms are tapered for the large GM tie rod ends. These are not the same as the draglink ends, be aware. We can custom build the steering arm with no hole if you wish, or the holes can be drilled out for a heim joint. We've had the best luck with using factory type tie rod ends for steering since they are a better single shear connection and have good service life.

The Offroad Design D44 steering arm end is cut on an angle to correct for the ball joint axis inclination angle and keep the angle on the rod end minimized for best life of the joint and more vertical wheel travel without steering bind. We've attempted crossover steering systems using arms that aren't built with the angled end and the rod end was maxed out at ride height! No droop available at all. This is an essential feature for a properly built fully functional system. 4 tapered holes to work with stock or aftermarket knuckles.

ARP Stud Kit: (Set of 4 ARP High Strength, 190,000+ psi studs)

Draglink: (This is the link that ties the pitman arm and steering arm together. We sell the tube threaded on each end with the ends installed)

Tie Rod Ends: (1 LH, 1 RH with jam nuts and castle nuts. These are a new HD end with angle capability similar to a GM draglink end but with the short strong shank of a tie rod end.

Our tie rod ends are manufactured specifically for us. Factory GM draglink ends have good angle capacity, but have long shanks that can cause clearance issues. Factory GM tie rod ends are nice and short, but have very little angle capacity. Our ends are built with the best of both worlds, this is crucial in many applications (particularly 67-87 GM straight axle trucks) as many times the bend in the draglink has to start as soon as possible to clear the engine crossmember, the extra shank on draglink ends makes that impossible.

Additionally, our tie rod ends are a metal-on-metal design with a preload spring on the bearing race (sort of like the upper kingpin on a Dana 60), that helps keep the joint tight even as the parts wear.)